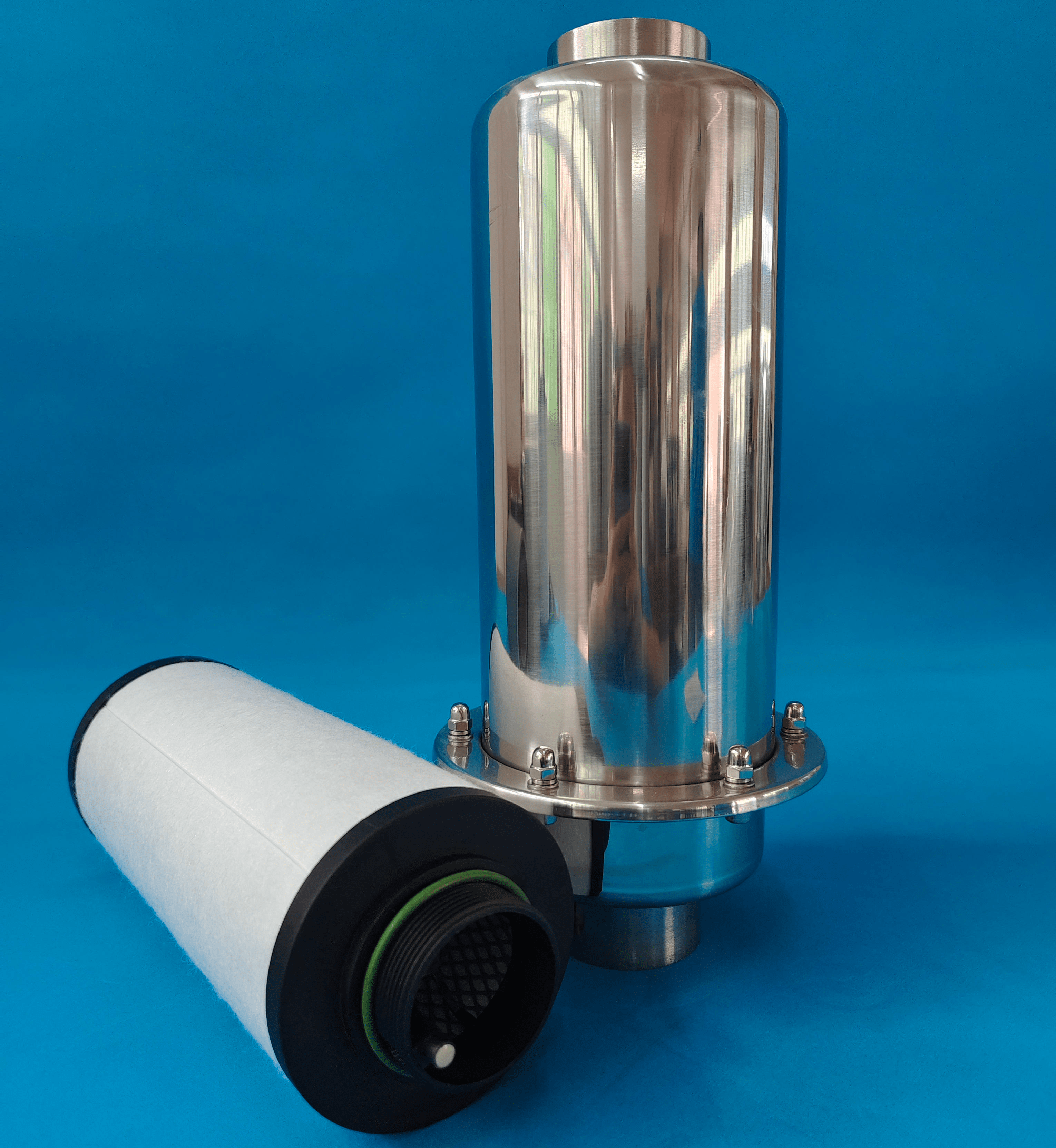

The significant development of vacuum technology has made it closely related to various industries, including the modern pharmaceutical industry. Nowadays, the use of vacuum technology in pharmaceuticals is commonplace. In the pharmaceutical industry, vacuum is usually mainly used in the following processes of pharmaceuticals: distillation, purification, vacuum feeding, mixing, reaction, evaporation, concentration, drying, extraction, and sublimation. According to the process requirements, there are different requirements for the structure and vacuum degree of the vacuum pump, and higher requirements are also put forward for the vacuum pump filter.

In these processes, the following types of vacuum equipment are mainly used: reciprocating vacuum pump, rotary vane vacuum pump, dry Roots vacuum pump, and vacuum pump unit. In the past, the application of vacuum in the pharmaceutical industry was not widespread, and the requirements were not high. Small vacuum pumps with smaller suction volumes were often used. After the continuous development of the industry, it is now mainly focused on medium and large pumps and vacuum units. These large and medium-sized pumps and vacuum units generally rely on matching vacuum pump filters to maintain the normal operation of vacuum equipment.

制药行业由于其本身的特殊性,对真空技术广泛应用的同时也对创造真空条件的真空泵要求甚多,它需要使用的真空泵工作可靠、结构紧凑、密封良好。在真空泵的尺寸上需要利于操作、清洁和维护。在用于输送介质时,保证不造成新的污染。必要时,还需要真空泵测试的详细数据作为参考。这些不断延伸的需求,给真空泵以及真空泵过滤器厂家的设计能力提出了越来越高的要求。

+86 10-64730110

+86 10-64730100